When Customers engaged Green Pine Technologies for DLC coating, They are usually seeking for the followings:

> Tetrahedral Amorphous Carbon (TaC)

Tetrahedral Amorphous Carbon (TaC)

Tetrahedral Amorphous Carbon (Tac) is one type of Carbon coating with the highest hardness in the market, at 5,000 Hv next to Poly-Crystallized Diamond which is at 10,000 Hv.

Because of its high hardness, it has very good abrasion wear resistant, making this coating very suitable for coating on Cutting tools.

Tetrahedral Amorphous Carbon (Tac) is very suitable for Non-ferrous steel, CFRP or composite materials and Graphite materials cutting.

And with coating thickness of not more than one micron, there is no worries that your tools will be out of tolerances.

Tetrahedral Amorphous Carbon (TaC)

Coating material:

Coating colour:

Coating hardness:

Coefficient of friction (dry) vs. steel:

Max. service temp. [°C]:

Process temp. [°C]:

ta-C

Grey

5000 Hv

0.1~0.2

500

120

Please fill in the contact form to get in touch with us by clicking on the button below.

Diamond Like Carbon (DLC)

This DLC coating is one type of DLC with Hydrogen content. With its hardness range from 2000 to 2500 Hv, it is usually coated on the moving and sliding parts of injection moulding tools for its abrasion wear resistant and it’s tribological performance.

Diamond Like Carbon (DLC)

Coating material:

Coating colour:

Coating hardness:

Coefficient of friction (dry) vs. steel:

Max. service temp. [°C]:

Process temp. [°C]:

a-C:H

Black

2000 ~ 2500Hv

0.1~0.2

300

230

Please fill in the contact form to get in touch with us by clicking on the button below.

Diamond Like Carbon coating commonly known as DLC coating exists in many forms, It can be either with Hydrogen or Hydrogen free. One of the way in the industries to improve on the different properties of DLC coating is by chemical doping with foreign metals.

DYLYN Coating

Dylyn coating is a DLC coating that has been doped with Silicon, resulting this coating with extremely low coefficient of friction.

Dylyn coating is very suitable for Plastic Injection molding for demolding especially when you are dealing with very sticky material like Silicone.

DYLYN Coating

Coating material:

Coating colour:

Coating hardness:

Coefficient of friction (dry) vs. steel:

Max. service temp. [°C]:

Process temp. [°C]:

a-C:H:Si

Black

2000 ~ 2500Hv

0.1~0.2

350

220

Please fill the contact form to get in touch with us by clicking the button below.

ESD DLC Coating

An Electrostatic Discharge (ESD) will cause physical damges in electrical devices and lowers their production yield. As electrostatic charge is maintained on insulative surfaces, a slow discharge is necessary as it reduces the electrical stress on the devices and protects them from ESD damage due to the suppression of high current surge.

The ESD DLC coatings in the semiconductor industry would be highly seek after as an excellent solution to raise production yield due to their provision of ESD protection and their good tribological properties.

ESD DLC Coating

Coating material:

Coating colour:

Coating hardness:

Coefficient of friction (dry) vs. steel:

Resistivity in Ohms @100V

Max. service temp. [°C]:

Process temp. [°C]:

a-C:H

Black

2000 ~ 2500Hv

0.1~0.2

10^5 <10^9

300

230

Please fill in the contact form to get in touch with us by clicking on the button below.

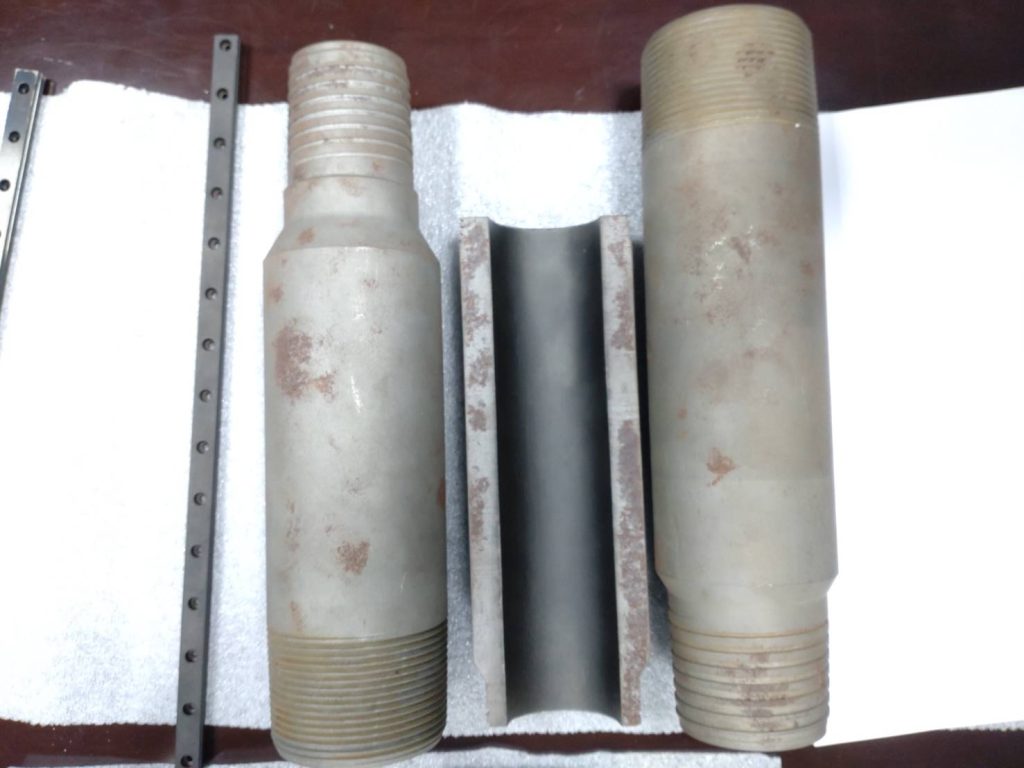

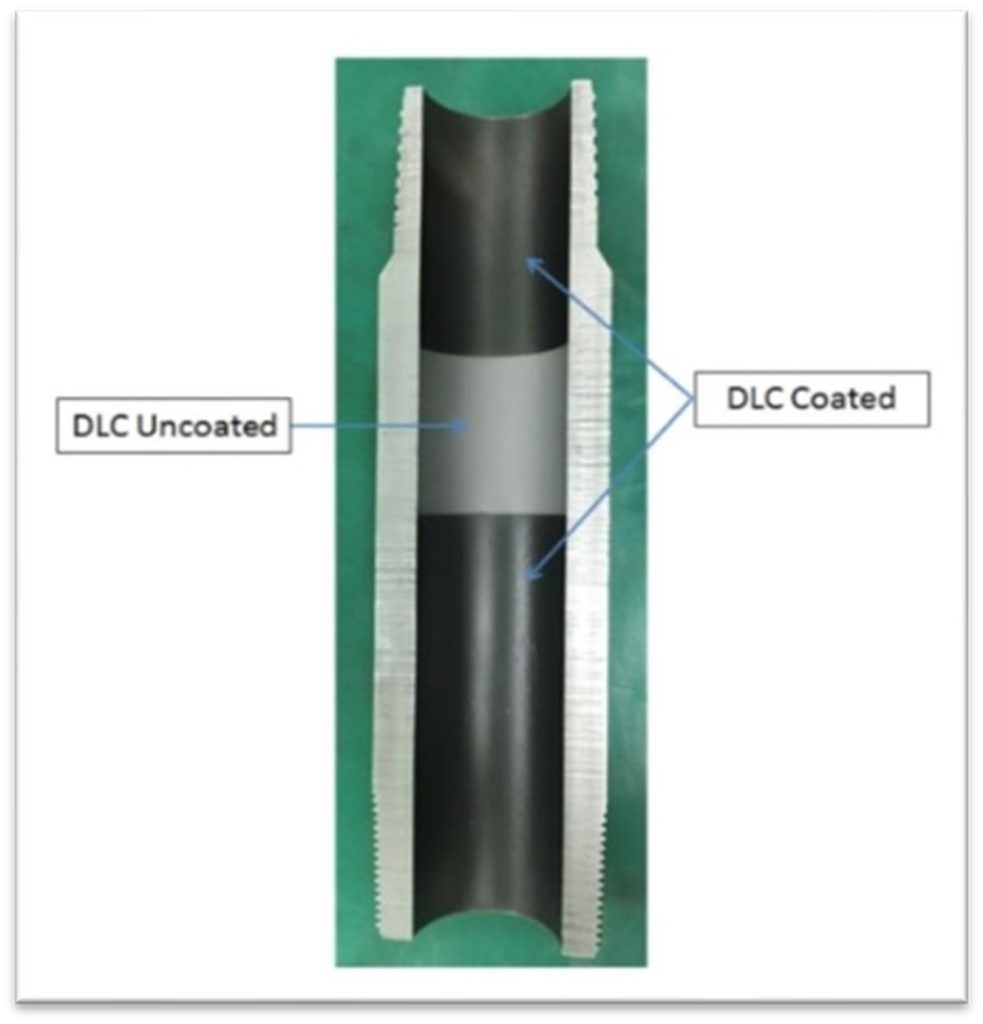

The DLC Internal Coating

The DLC Internal Coating is a PECVD coating process with a patented technology utilizing the hollow-cathode ion immersion process.

This process eliminates the limitation of PVD process whereby coating on the internal diameter of a shaft is always a challenge. In theory, to coat the internal diameter of a shaft by normal PVD process, if the internal diameter is 10 mm, the depth of the coating in the internal is around 10mm, but in practice, it may not be the case and the thickness of the coating at the internal surface is quite negligible.

With the DLC Internal Coating, we are able to solve this issue totally. The aspect ratio of the coating in the internal is 12:1. Which means that if the internal diameter of the shaft is 10mm, the length of the shaft in the internal that we can coat is around 120mm.

The DLC Internal Coating

Coating material:

Coating colour:

Coating hardness:

Coefficient of friction (dry) vs. steel:

Max. service temp. [°C]:

Process temp. [°C]:

Coating thickness:

Recommended thickness:

Smallest internal diameter able to coat:

a-C:H

Black

2000 ~ 2500Hv

0.1~0.2

400 to 500

250

From 1 to 50 microns

6 to 8 microns

5mm

Applications of The DLC Internal Coating

The DLC Internal Diameter coating is suitable for use in the Plastic Injection Moulding whereby the coating of the internal diameter of the Unscrew mould inserts or Thread core inserts is a challenge. The DLC Internal Diameter will provide a highly lubricated dry surface which is highly resistance to scrolling and abrasion wear.

In the Oil and Gas industries, Crossover Sub and nipples are often coated with DLC Internal Diameter coating to prevent wear, erosion, and corrosion. The limitation of the PVD coating process to coat the internal surface with a consistent thickness is being eliminated. With the DLC Internal Diameter coating, you can be rest assured that the internal of the shaft can be coated with a consistent thickness throughout the entire length.